HYC气动执行器

model | A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | A120 | A180 | Airconnection |

QH052 | 143 | 72 | 55 | 92 | 30 | 41 | 14 | 80 | 30 | F05∅50 | F03∅36 | M6x8 | M5X8 | 11 | ∅40 | 158 | 200 | G1/8” |

QH063 | 190 | 88 | 69 | 108 | 35 | 45 | 18 | 80 | 30 | F07∅70 | F05∅50 | M8X13 | M6X10 | 14 | ∅40 | 184 | 233 | G1/4” |

QH075 | 207 | 99.5 | 100.5 | 119.5 | 38.5 | 52.5 | 20.5 | 80 | 30 | F07∅70 | F05∅50 | M8X10 | M6x8 | 14 | ∅40 | 103 | 243 | G1/4” |

QH083 | 213 | 109 | 88 | 129 | 46 | 52.5 | 21 | 80 | 30 | F07∅70 | F05∅50 | M8X13 | M6x10 | 17 | ∅40 | 221 | 280 | G1/4” |

QH092 | 258 | 117 | 98.5 | 137 | 50 | 61 | 21 | 80 | 30 | F07∅70 | F05∅50 | M8X12 | M6x10 | 17 | ∅40 | 280 | 274 | G1/4” |

QH105 | 267 | 133 | 109 | 153 | 57 | 64 | 26 | 80 | 30 | F10∅102 | F07∅70 | M10X13 | M8X10 | 22 | ∅40 | 304 | 388 | G1/4” |

QH125 | 340 | 155 | 120.5 | 175 | 67.5 | 70 | 27.5 | 80 | 30 | F10∅102 | F07∅70 | M10X16 | M8x13 | 22 | ∅65 | 365 | 470 | G1/4” |

QH140 | 414 | 171.5 | 132 | 191.5 | 75 | 76 | 32 | 80 | 30 | F12∅125 | F10∅102 | M12X20 | M10x15 | 27 | ∅65 | 442 | 568 | G1/4” |

model | Input air source pressure (in units:bar) | ||||||

2 | 3 | 4 | 5 | 6 | 7 | 8 | |

QH 032DA | 2.78 | 4.20 | 6.00 | 7.50 | 9.00 | 10.00 | 11.5 |

QH 052DA | 8.32 | 12.48 | 16.64 | 20.8 | 24.96 | 29.12 | 33.28 |

QH 063DA | 14.64 | 21.96 | 29.28 | 36.6 | 43.92 | 51.24 | 58.76 |

QH 075DA | 23.5 | 35.3 | 47 | 58.5 | 70.5 | 82.3 | 94 |

QH 083DA | 29.7 | 44.5 | 59.4 | 74.2 | 89.1 | 103.9 | 118.9 |

QH 092DA | 45.5 | 68.2 | 91.1 | 113.7 | 136.4 | 159.2 | 1189 |

QH 105DA | 67.88 | 101.82 | 136.76 | 169.7 | 203.64 | 237.58 | 371.52 |

QH 125DA | 116.6 | 174.9 | 233.2 | 291.5 | 349.8 | 408.1 | 466.4 |

QH 140DA | 175.48 | 263.22 | 350.96 | 438.7 | 526.44 | 614.18 | 701.92 |

QH 160DA | 267.4 | 401.1 | 534.8 | 668.5 | 802.2 | 935.9 | 1069.6 |

QH 190DA | 430.96 | 646.44 | 861.9 | 1077.4 | 1292.9 | 1508.4 | 1723.8 |

QH 210DA | 592.2 | 888.4 | 1184.5 | 1480.6 | 1776.7 | 2072.8 | 2369 |

QH 240DA | 928.3 | 1392.5 | 1156.6 | 2320.8 | 2785 | 3249.1 | 3713.3 |

HYC single acting actuator output torque

Output torque of air to springs | Spring output torque | ||||||||||||

Mpa | 3 | 4 | 5 | 6 | 7 | ||||||||

| model | Number of springs | 0° | 90° | 0° | 90° | 0° | 90° | 0° | 90° | 0° | 90° | 0° | 90° |

starting point | End | starting point | End | starting point | End | starting point | End | starting point | End | starting point | End | ||

QH052SA | 5 | 8.48 | 6.28 | 12.64 | 10.44 |

|

|

|

|

|

| 4 | 6.2 |

6 | 7.68 | 4.98 | 11.84 | 9.14 |

|

|

|

|

|

| 4.8 | 7.5 | |

7 | 6.98 |

| 11.14 | 7.94 |

|

|

|

|

|

| 5.5 | 8.7 | |

8 |

| 3.78 | 10.34 | 6.74 | 14.5 | 10.9 |

|

|

|

| 6.3 | 9.9 | |

9 |

|

| 9.54 | 5.44 | 13.7 | 9.6 |

|

|

|

| 7.1 | 11.2 | |

10 |

|

| 8.74 | 4.24 | 12.9 | 8.4 | 17.6 | 12.56 |

|

| 7.9 | 12.4 | |

11 |

|

|

|

| 12.1 | 7.1 | 16.26 | 11.26 | 20.42 | 15.42 | 8.7 | 13.7 | |

12 |

|

|

|

| 11.3 | 5.9 | 15.46 | 10.06 | 19.62 | 14.22 | 9.5 | 14.9 | |

QH063SA | 5 | 15 | 11.2 | 22.3 | 18.5 | 29.6 | 25.8 |

|

|

|

| 7 | 10.8 |

6 | 13.5 | 9 | 20.8 | 16.3 | 28.1 | 23.7 |

|

|

|

| 8.5 | 12.95 | |

7 | 12 | 6.9 | 19.4 | 14.2 | 26.7 | 21.5 |

|

|

|

| 9.9 | 15.1 | |

8 |

|

| 18 | 12 | 25.3 | 19.3 | 32.6 | 26.6 |

|

| 11.3 | 17.3 | |

9 |

|

| 16.5 | 9.9 | 23.9 | 17.2 | 31.2 | 24.52 |

|

| 12.7 | 19.4 | |

10 |

|

| 15.3 | 7.7 | 22.6 | 15 | 29.9 | 22.3 | 37.2 | 29.6 | 14 | 21.6 | |

11 |

|

| 13.8 | 5.6 | 21.1 | 12.9 | 28.4 | 20.2 | 35.7 | 27.5 | 15.5 | 23.7 | |

12 |

|

|

|

| 19.7 | 10.7 | 27 | 18 | 34.3 | 25.3 | 16.9 | 25.9 | |

QH075SA | 5 | 23.4 | 17.8 | 35.1 | 29.5 |

|

|

|

|

|

| 11.9 | 17.5 |

6 | 21.1 | 14.3 | 32.8 | 26 |

|

|

|

|

|

| 14.2 | 21 | |

7 | 18.7 | 10.8 | 30.4 | 22.5 |

|

|

|

|

|

| 16.6 | 24.5 | |

8 |

|

| 28 | 19 | 39.8 | 30.8 |

|

|

|

| 19 | 27 | |

9 |

|

| 25.7 | 15.5 | 37.5 | 27.3 |

|

|

|

| 21.3 | 31.5 | |

10 |

|

| 23.3 | 12 | 35.1 | 23.8 | 46.8 | 35.5 | 58.6 | 47.3 | 23.7 | 35 | |

11 |

|

|

|

| 32.7 | 20.3 | 44.4 | 32 | 56.2 | 43.8 | 26.1 | 38.5 | |

12 |

|

|

|

| 30.4 | 16.8 | 42.1 | 28.5 | 53.9 | 40.3 | 28.4 | 42 | |

QH083SA | 5 | 30.9 | 23.8 | 46.1 | 38.9 |

|

|

|

|

|

| 14.5 | 21.7 |

6 | 28.1 | 19.5 | 43.3 | 34.6 |

|

|

|

|

|

| 17.39 | 26 | |

7 | 25.2 | 15.1 | 40.3 | 30.2 |

|

|

|

|

|

| 20.3 | 30.4 | |

8 |

|

| 37.4 | 25.9 | 52.6 | 41.1 |

|

|

|

| 23.2 | 34.7 | |

9 |

|

| 34.5 | 21.5 | 49.7 | 36.7 |

|

|

|

| 26.1 | 39.1 | |

10 |

|

| 36.1 | 17.2 | 46.8 | 32.4 | 62 | 47.6 | 77.1 | 62.7 | 29 | 43.4 | |

11 |

|

|

|

| 43.9 | 28.1 | 59.1 | 43.3 | 74.2 | 58.4 | 31.9 | 47.7 | |

12 |

|

|

|

| 41 | 23.7 | 56.2 | 38.8 | 71.3 | 54 | 34.78 | 52.08 | |

QH0925A | 5 | 50.28 | 37.78 | 75.54 | 63.03 |

|

|

|

|

|

| 25.5 | 38 |

6 | 45.18 | 30.18 | 70.44 | 55.44 |

|

|

|

|

|

| 30.6 | 45.6 | |

7 | 40.08 | 22.58 | 65.35 | 47.84 |

|

|

|

|

|

| 35.7 | 53.2 | |

8 |

|

| 60.24 | 40.24 | 85.5 | 65.5 |

|

|

|

| 40.8 | 60.8 | |

9 |

|

| 55.14 | 32.69 | 80.4 | 57.9 |

|

|

|

| 45.9 | 68.4 | |

10 |

|

| 50.04 | 25.04 | 75.3 | 50.3 | 100.56 | 75.56 | 125.82 | 100.82 | 51 | 76 | |

11 |

|

|

|

| 70.2 | 42.7 | 95.46 | 67.96 | 12.72 | 93.22 | 26.1 | 83.6 | |

12 |

|

|

|

| 65.1 | 35.1 | 90.36 | 60.36 | 115.6 | 85.6 | 61.2 | 91.2 | |

QH105SA | 5 | 68.6 | 52 | 103.6 | 87 |

|

|

|

|

|

| 33.2 | 49.8 |

6 | 61.9 | 42 | 96.9 | 77 |

|

|

|

|

|

| 39.9 | 59.8 | |

7 | 55.3 | 32.1 | 90.3 | 67.1 |

|

|

|

|

|

| 46.5 | 69.7 | |

8 |

|

| 83.7 | 57.1 | 116.6 | 90 |

|

|

|

| 53.1 | 79.7 | |

9 |

|

| 77 | 47.1 | 109.9 | 80.3 |

|

|

|

| 59.8 | 89.4 | |

10 |

|

| 70.4 | 37.2 | 103.3 | 70.1 | 137.3 | 104 | 171.2 | 138 | 66.4 | 99.6 | |

11 |

|

|

|

| 96.7 | 60.1 | 130.6 | 94 | 164.6 | 128 | 73 | 109.6 | |

12 |

|

|

|

| 90 | 50.2 | 123.9 | 64.1 | 157.9 | 118.1 | 79.7 | 119.5 | |

QH125SA | 5 | 115.5 | 88 | 173.8 | 146.3 |

|

|

|

|

|

| 59.4 | 86.9 |

6 | 103.6 | 70.6 | 161.9 | 128.9 |

|

|

|

|

|

| 71.3 | 104.3 | |

7 | 91.8 | 53.5 | 150.1 | 111.6 |

|

|

|

|

|

| 83.1 | 121.6 | |

8 |

|

| 138.2 | 94.2 | 196.5 | 152.5 |

|

|

|

| 95 | 139 | |

9 |

|

| 126.3 | 76.8 | 184.6 | 135.1 |

|

|

|

| 106.9 | 156.4 | |

10 |

|

| 114.4 | 49.4 | 172.7 | 117.7 | 231 | 176 |

|

| 118.8 | 173.8 | |

11 |

|

|

|

| 160.9 | 100.4 | 219.2 | 158.7 | 277.5 | 217 | 130.6 | 191.1 | |

12 |

|

|

|

| 149 | 83 | 207.3 | 141.3 | 265.6 | 199.6 | 142.5 | 208.5 | |

QH140SA | 5 | 174.7 | 131.2 | 262.5 | 219 |

|

|

|

|

|

| 88.5 | 132 |

6 | 157 | 104.8 | 244.8 | 192.6 |

|

|

|

|

|

| 106.2 | 158.4 | |

7 | 133.9 | 78.4 | 227.1 | 166.2 |

|

|

|

|

|

| 123.9 | 184.8 | |

8 |

|

| 209.4 | 139.8 | 297.1 | 227.5 |

|

|

|

| 141.6 | 211.2 | |

9 |

|

| 191.7 | 113.4 | 279.4 | 201.1 |

|

|

|

| 159.3 | 237.6 | |

10 |

|

| 174 | 87 | 261.7 | 174.7 | 349.4 | 262.4 | 437.8 | 350.1 | 177 | 264 | |

11 |

|

|

|

| 244 | 148.3 | 331.7 | 236 | 419.5 | 323.8 | 194.7 | 290.4 | |

12 |

|

|

|

| 226.3 | 121.9 | 314 | 209.6 | 401.8 | 297.4 | 212.4 | 316.8 | |

QH160SA | 5 | 264.6 | 197.1 | 398.3 | 330.8 |

|

|

|

|

|

| 136.5 | 204 |

6 | 237.3 | 156.2 | 371 | 289.9 |

|

|

|

|

|

| 163.8 | 244.9 | |

7 | 210 | 115.4 | 343.7 | 249.1 |

|

|

|

|

|

| 191.1 | 285.7 | |

8 | 182.7 | 74.6 | 316.4 | 208.3 | 450.1 | 341.9 |

|

|

|

| 218.4 | 326.5 | |

9 |

|

| 289.1 | 167.5 | 422.8 | 301.2 |

|

|

|

| 245.7 | 367.3 | |

10 |

|

| 261.8 | 126.7 | 395.5 | 260.4 | 529.2 | 394.1 |

|

| 273 | 408.1 | |

11 |

|

|

|

| 368.2 | 219.6 | 501.9 | 523.3 | 635.6 | 487 | 300.3 | 488.9 | |

12 |

|

|

|

| 340.9 | 178.8 | 474.6 | 312.5 | 608.3 | 446.2 | 327.6 | 489.7 | |

QH190SA | 5 | 429 | 320.4 | 644.5 | 535.9 |

|

|

|

|

|

| 217.4 | 326 |

6 | 385.5 | 255.5 | 601 | 470.7 |

|

|

|

|

|

| 260.9 | 391.2 | |

7 | 342 | 190 | 557.5 | 405.5 |

|

|

|

|

|

| 304.4 | 456.4 | |

8 |

|

| 514 | 340.3 | 729.5 | 555.8 |

|

|

|

| 347.9 | 521.6 | |

9 |

|

| 470.6 | 275.1 | 686.1 | 490.6 |

|

|

|

| 391.3 | 586.8 | |

10 |

|

| 427.1 | 209.9 | 642.6 | 425.4 | 858.1 | 640.9 | 1073.6 | 856.4 | 434.8 | 652 | |

11 |

|

|

|

| 599.1 | 360.2 | 814.6 | 575.7 | 1030.1 | 791.2 | 478.3 | 717.2 | |

12 |

|

|

|

| 555.6 | 295 | 771.1 | 510.5 | 986.6 | 726 | 521.3 | 782.4 | |

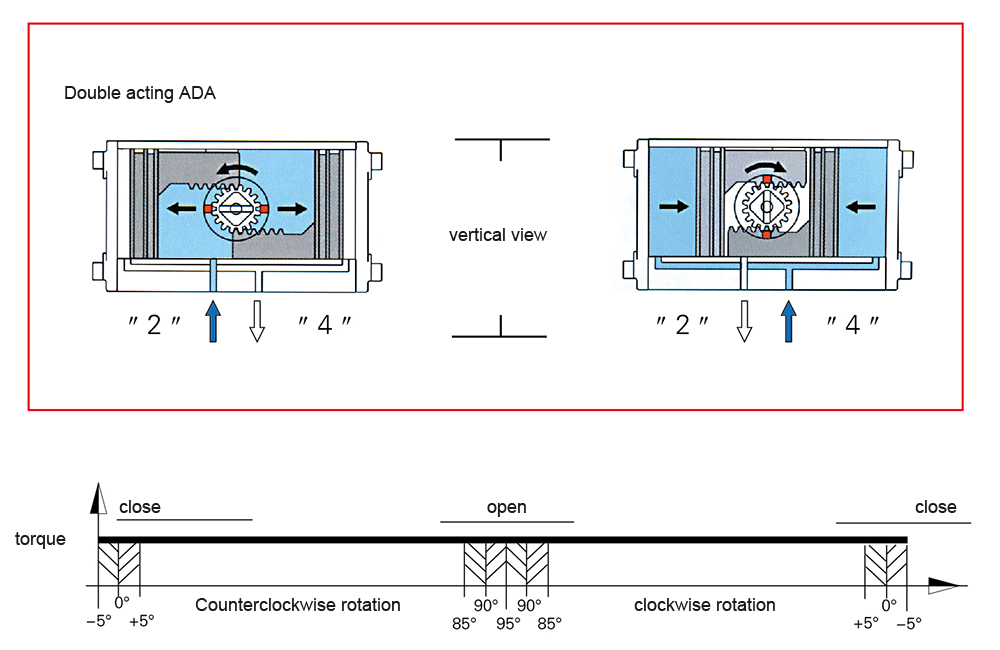

Working principle (standard action)

The above schematic diagram indicates that the torque value of the dual action actuator remains constant throughout the entire stroke. Users can select the appropriate actuator model based on their specific requirements and refer to the following content:

1. Clarify the larger torque value of the operated valve;

2. Increase the torque value by 25% to 50% with a set coefficient (depending on the valve type and process conditions);

3. According to the provided torque value, refer to the torque table and the corresponding air pressure value. The obtained torque value should be equal to or exceed the provided torque value;

After the torque value is determined, move horizontally to the "Model" column and find the desired actuator model.

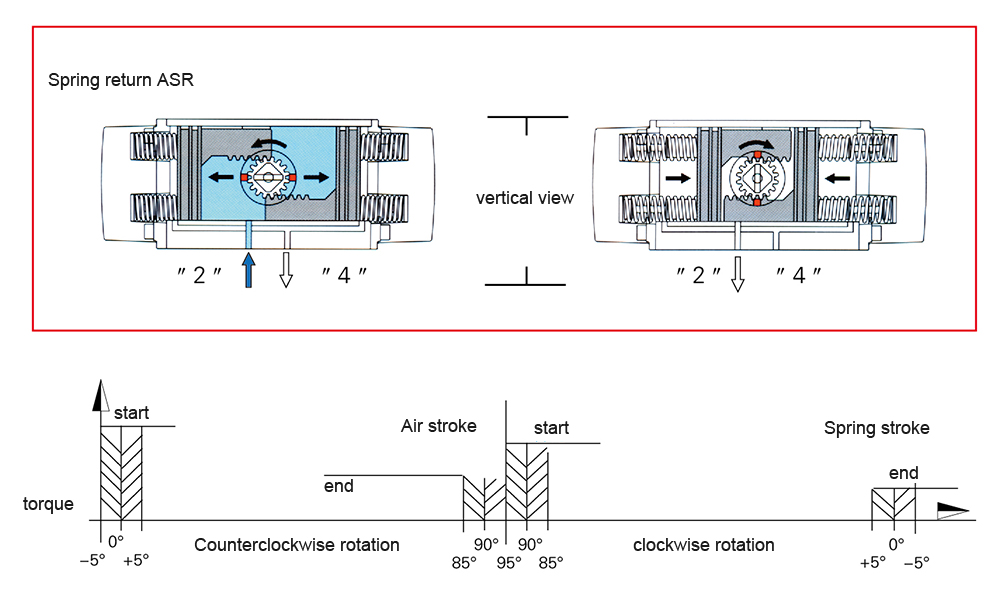

The schematic above shows that the torque of the spring return actuator is not constant but gradually decreasing. The main reason is that the spring is compressed during the air stroke stage due to the movement of the piston, while accumulating energy obtained in a continuously decreasing manner during the motion conversion process. The torque of the actuator is defined according to the following four basic values:;

Air stroke: Start: actuator torque in spring released state End: actuator torque in spring compression state

Spring stroke: Start: Torque during spring compression End: Torque when the spring is released

Users can select the appropriate actuator model based on their specific requirements and refer to the following content:

1. Clarify the larger torque value of the operated valve;

2. Increase the torque value by 25% to 50% and set a safety factor (depending on the valve type and process conditions);

3. Based on the provided torque values, refer to the torque table and the corresponding air pressure values. The obtained torque value should be equal to or exceed the provided torque value, and in addition, the minimum value between the end of the air stroke and the end of the spring stroke should be taken into account;

After the torque value is determined, move horizontally to the "Model" column and find the desired actuator model.